The Improved Stopping Power Of Performance Brake Rotors Over Stock Brake Rotors

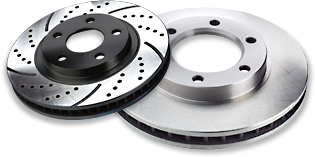

Customers always ask, what is the advantage of drilled and or slotted brake rotors over stock plain brake rotors? The advantage of slots is that it dramatically improves stopping power. Each brake disc is machined with four to five slots per side, depending on the vehicle, that extends off the edge of the rotor surface to remove dust and water away from the brake pad surface keeping the vehicle wheels cleaner and allowing for better braking. Additional benefit of the slots is the way it cools the brake pad and rotor surface eliminating brake fade or loss of braking ability. Second most commonly asked question is, what do the holes do? The advantage of the drilled holes is to allow heat that has built up between the rotor and brake pad surface to dissipate when your vehicle has been driven for long periods of time.This dissipation of heat will help prevent rotor warping and extend the life of your brake rotor. There are two types of holes that are offered on performance rotors, dimpled drilled and cross drilled. The dimpled holes are drilled without braking the pad surface which allows for heat dissipation while keeping the rotors structurally strong for vehicle's that are heavier or have inherit problems with warping rotors. Cross drilled holes are completely drilled through both disc surfaces allowing air to pass through and heat to dissipate. This drilling process is commonly used on rotors installed on light to medium duty vehicles including high performance vehicles. The substantial improvement in braking you will feel and the warranty that is included with every performance drilled and slotted brake rotor, is worth the upgrade over stock replacement rotors.

Customers always ask, what is the advantage of drilled and or slotted brake rotors over stock plain brake rotors? The advantage of slots is that it dramatically improves stopping power. Each brake disc is machined with four to five slots per side, depending on the vehicle, that extends off the edge of the rotor surface to remove dust and water away from the brake pad surface keeping the vehicle wheels cleaner and allowing for better braking. Additional benefit of the slots is the way it cools the brake pad and rotor surface eliminating brake fade or loss of braking ability. Second most commonly asked question is, what do the holes do? The advantage of the drilled holes is to allow heat that has built up between the rotor and brake pad surface to dissipate when your vehicle has been driven for long periods of time.This dissipation of heat will help prevent rotor warping and extend the life of your brake rotor. There are two types of holes that are offered on performance rotors, dimpled drilled and cross drilled. The dimpled holes are drilled without braking the pad surface which allows for heat dissipation while keeping the rotors structurally strong for vehicle's that are heavier or have inherit problems with warping rotors. Cross drilled holes are completely drilled through both disc surfaces allowing air to pass through and heat to dissipate. This drilling process is commonly used on rotors installed on light to medium duty vehicles including high performance vehicles. The substantial improvement in braking you will feel and the warranty that is included with every performance drilled and slotted brake rotor, is worth the upgrade over stock replacement rotors.

The Difference Between Semi Metallic and Ceramic Brake Pads

When deciding what brake pads are best for your vehicle, there are many factors to consider. The type of driving, weight of your vehicle and what is recommended by the manufacturer. Premium semi metallic brake pads are perfect for all light, medium to heavy duty cars, trucks, and SUV's. This type of pad is highly recommended for heavy work trucks, towing applications, performance vehicles, European vehicles and any vehicles experiencing warped brake rotor/discs due to excessive heat. These pads are manufactured with a high temperature fade resistance and a high friction level. They are simply the best pads for handling high heat and providing noise free braking. Ceramic brake pads are ideal for medium to light duty US Domestic, Japanese/Korean, Cars, Trucks and SUV's. These Pads are designed to wear longer and have less brake dust than the semi metallic pads. Ceramic pads are NOT recommended for heavy cars, trucks, SUV's or performance vehicles because they do not have a high temperature fade resistance and could warp rotors because of the heat factor. Both types of pads will give you great stopping performance and the information provided hopefully will help you make the correct decision.

When deciding what brake pads are best for your vehicle, there are many factors to consider. The type of driving, weight of your vehicle and what is recommended by the manufacturer. Premium semi metallic brake pads are perfect for all light, medium to heavy duty cars, trucks, and SUV's. This type of pad is highly recommended for heavy work trucks, towing applications, performance vehicles, European vehicles and any vehicles experiencing warped brake rotor/discs due to excessive heat. These pads are manufactured with a high temperature fade resistance and a high friction level. They are simply the best pads for handling high heat and providing noise free braking. Ceramic brake pads are ideal for medium to light duty US Domestic, Japanese/Korean, Cars, Trucks and SUV's. These Pads are designed to wear longer and have less brake dust than the semi metallic pads. Ceramic pads are NOT recommended for heavy cars, trucks, SUV's or performance vehicles because they do not have a high temperature fade resistance and could warp rotors because of the heat factor. Both types of pads will give you great stopping performance and the information provided hopefully will help you make the correct decision.

Note: We carry the largest selection of new brake products for the following manufacturers: Ford, Chevrolet, Dodge , Toyota, Nissan, Honda, Hyundai and more

Enter Contests to Win Free Merchandise!

Enter Contests to Win Free Merchandise!

Tweet Us For Links To Sales & Videos!

Tweet Us For Links To Sales & Videos!

See Photos Of The Cars We Love!

See Photos Of The Cars We Love!

View Installation & Product Videos!

View Installation & Product Videos!